In mines, outdoor construction and remote sites, power issues hobble dust suppression. Traditional electric mist cannon machines rely on external power, being ineffective in grid - less or outage - prone areas. Diesel - generator - integrated mist cannon machines, with independent power and efficient dust - suppression, break this deadlock.

Challenges in Power - Deficient Dust Suppression

1. Inadequate Power Infrastructure

High - cost transmission lines leave 60% of electric mist cannon machines near main roads in open - pit mines. Temporary construction sites waste 30% of working hours on power connection. Unstable grids in extreme regions cause over 40% shutdowns during outages.

2. Traditional Equipment's Shortcomings

Voltage fluctuations cut PM2.5 capture from 65% to 40%. Battery - powered devices with 4 - 6 - hour endurance lead to 50% night - time dust rebounds. Lacking heating/cooling, over 30% of devices fail in extreme temperatures.

3. High Operation and Maintenance Costs

Remote - area repairs take over 12 hours and cost over 5,000 yuan. Unmanaged parallel devices waste 25% of energy.

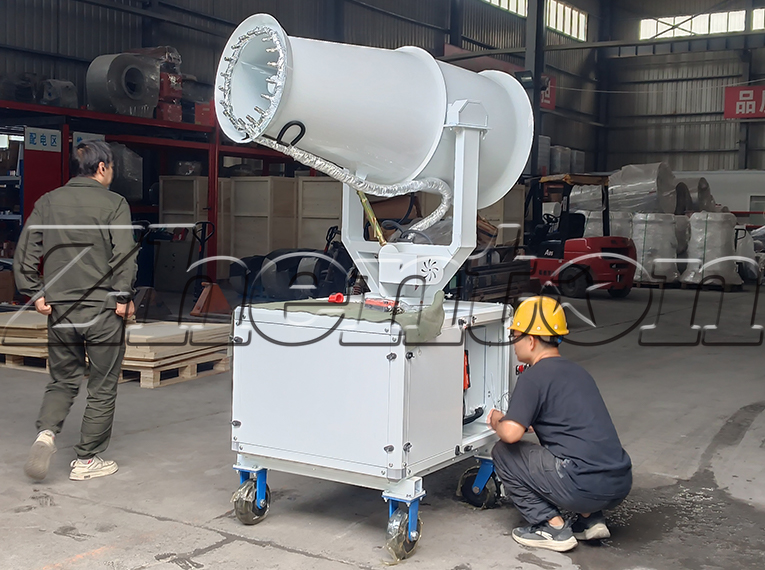

Advantages of Diesel - Generator Mist Cannon Machines

1. Self - sufficient Power Generation

490/6105 series diesel engines (30 - 100kW) enable - 25°C startup and 45°C operation, with 100% startup at 4,000 - meter - altitude mines. 200 - 500L fuel tanks offer 12 - 20 - hour runtime (50 - meter range model), saving 15% fuel. Remote startup reaches full power in 30 seconds.

2. Efficient Dust Suppression

Aviation vortex atomization adjusts droplet size (20 - 200μm), achieving 92% PM2.5 capture. 50 - 150 - meter range with 360° rotation covers 20,000㎡. Dust sensors (±1% accuracy) boost pressure when PM10 ≥ 1.0mg/m³, with < 1 - minute response.

3. All - Terrain Adaptability

Off - road chassis and 10 - 16 - inch tires work on 30° - slope, 40% - mud roads, tripling operation range. Q345B steel, IP67 bearings extend maintenance to 3 months. Noise ≤ 85dB ensures quiet night work.

4. Intelligent Management Cuts Costs

4G/Beidou transmits real - time status, with < 5 - minute alarm response. 16 safety functions identify 90% of faults. 0#/-10# diesel switching raises winter adaptability by 60% and cuts costs by 40%.

Application Cases

1. Northwest Open - Pit Coal Mine

Challenge: 3 - km from substation, frequent tripping in rain.

Solution: 2 80 - meter range machines with 300L tanks in dispatch system.

Results: 16 - hour work, 14 - hour endurance, 200% efficiency boost. Dust down from 2x to 50% of standard, 50 shutdowns less, 200,000 yuan saved, 60% failure rate drop.

2. Mountain Road Construction

Challenge: High dust, unstable power during tunnel work.

Solution: 50 - meter vehicle - mounted machine with 50kW generator.

Results: PM2.5 down from 500μg/m³ to 80μg/m³, < 1 - minute startup, 30% cost savings, 15 - day schedule advance.

3. Border Port Cargo Yard

Challenge: Dust spread, ±20% voltage fluctuation.

Solution: 3 fixed 100 - meter machines with heating in auto - cruise.

Results: Stable operation, < 5% droplet deviation, 18 - hour night work, 80% complaint drop, smooth - start at - 15°C.

Purchase Guide

1. Power System

Prefer Yuchai, Weichai engines, avoid unbranded ones (3x failure rate). Ask for full - load tests, select ≥ 12 - hour endurance fuel tanks.

2. Dust Suppression Parameters

Droplet deviation < ±5%, < 20% range reduction in level 6 wind. Coastal areas need ≥ level 8 wind - resistance. Ensure dust - concentration or remote - start functions.

3. Life - Cycle Cost

Fuel - efficient models save 40,000 yuan/year. High - quality parts have ≥ 500 - hour maintenance. Check for 10 - 15% regional subsidies.

V. Industry Trends

With the Technical Policy for Pollution Prevention and Control of Non - Road Mobile Machinery, diesel - generator mist cannon machines account for 70% of new mine dust - suppression equipment. They are "mobile fortresses" in emergencies and see 40% annual export growth in Belt and Road countries. A southwest mining group's compliance rose from 45% to 92%, with 1.8 - times efficiency boost and 8 - month payback.

Conclusion

Diesel - generator mist cannon machines free dust suppression from power constraints, enabling 24/7 operation. They are essential in power - deficient areas. Choose the right one for effective dust control. Contact consultants for customized solutions.