Working

principle

principle

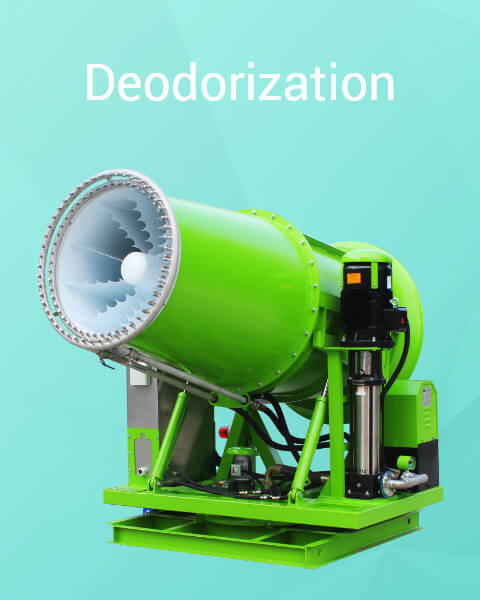

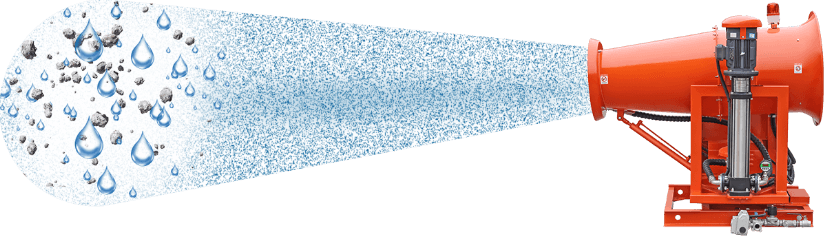

The working principle of the fog cannon machine is to use high air pressure to pressurize the water, and input it to the high-pressure nozzle atomization device through the pipeline to form a water mist floating in the air. The water mist is sent to a longer distance through the spraying system. It can absorb fine dust and suspended particles in the air to achieve dust reduction.

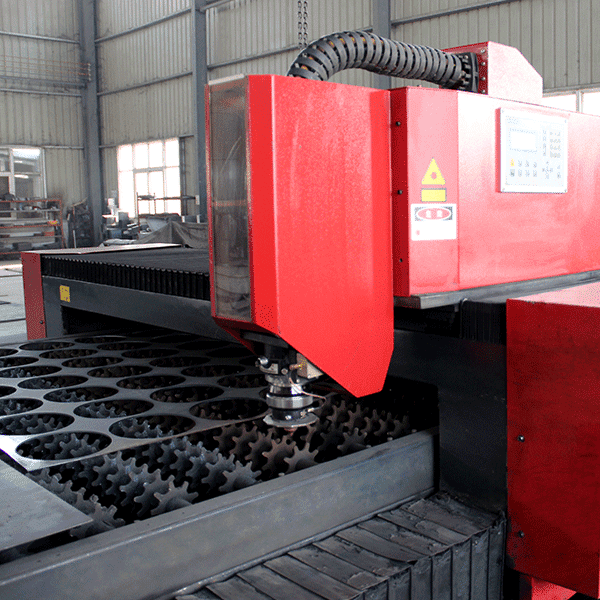

Zhengzhou Zhengtong Fan Manufacturing Co. , Ltd. is a research and development, manufacturing, sales as one of the professional fan manufacturing enterprises. The company HAS ADVANCED PRODUCTION EQUIPMENT AND PROFESSIONAL R & D team, innovative product design, fine technology, stable performance, Good quality.

Zhenton Fog Cannon Dust Suppression System

The Zhenton Fog Cannon has been engineered to tackle the complex problem of airborne dust particles generated by open-pit mining activities, general demolition work, and bulk material handling. Zhenton technology has been proven to suppress up to 95% of airborne dust particles, providing a cleaner and safer work environment for industrial operations worldwide.Flexible Solutions for Every ScaleOur smaller units are ideal for suppressing dust at high-concentration point sources, such as stockpile discharging, ship loading, reclaiming, crushing stations, and truck loading/unloading. In these scenarios, the Zhenton Fog Cannon is directed precisely at the em…

Cleaner Sites, Safer Cities: Fog Cannon Systems for Singapore Construction Projects

In a city like Singapore, construction sites are never isolated. They sit next to residential blocks, schools, offices, and busy roads. Dust generated on-site does not stay within boundaries—it affects public health, traffic safety, and the overall urban environment. That is why cleaner construction sites are closely linked to safer cities.Fog cannon dust suppression systems play an important role in achieving this balance. By releasing ultra-fine mist, fog cannons capture airborne dust before it spreads, helping construction activities coexist more smoothly with surrounding communities.Reducing Dust to Protect Public SafetyUncontrolled dust can reduce…

Why Fog Cannon Dust Suppression Is Becoming Standard on Singapore Construction Sites

Across Singapore, dust control is no longer handled as a temporary or reactive task. As construction activities move closer to residential areas and environmental oversight becomes stricter, many contractors now treat dust suppression as a standard site requirement rather than an optional add-on.Among various solutions, fog cannon dust suppression systems are increasingly becoming the preferred choice. By producing ultra-fine mist, fog cannons capture airborne dust particles directly at the source, preventing them from spreading across roads, nearby buildings, and public spaces. This proactive approach helps maintain cleaner sites and more stable workin…

From Complaints to Compliance: Dust Suppression Solutions for Singapore Job Sites

In Singapore, construction dust complaints can quickly escalate into inspections, penalties, or work delays. For contractors working close to residential areas, schools, or main roads, dust control is no longer optional—it is a core part of site compliance and reputation management.Modern fog cannon dust suppression systems offer a practical way to address this challenge. By generating ultra-fine mist, fog cannons capture airborne dust particles at the source, preventing them from spreading beyond site boundaries. Compared with manual water spraying, fog cannons provide wider coverage, more consistent performance, and better control with lower water us…

27

02

24

02

17

02

10

02