In the cement production process, the material discharge port serves as a key node for material transfer, often generating intense dust due to aggregate dumping and powder conveying. This pervasive dust not only pollutes the workshop environment and threatens workers' health but may also cause equipment failures due to dust accumulation. The mist cannon machine for dust control at cement plant material discharge ports, with its targeted technical solutions, acts as a precise "environmental protection blade," constructing an efficient prevention front at the source of dust dispersion, providing an innovative solution for cement enterprises to tackle dust problems at discharge ports.

Targeted Design: Addressing Core Pain Points of Discharge Port Dust

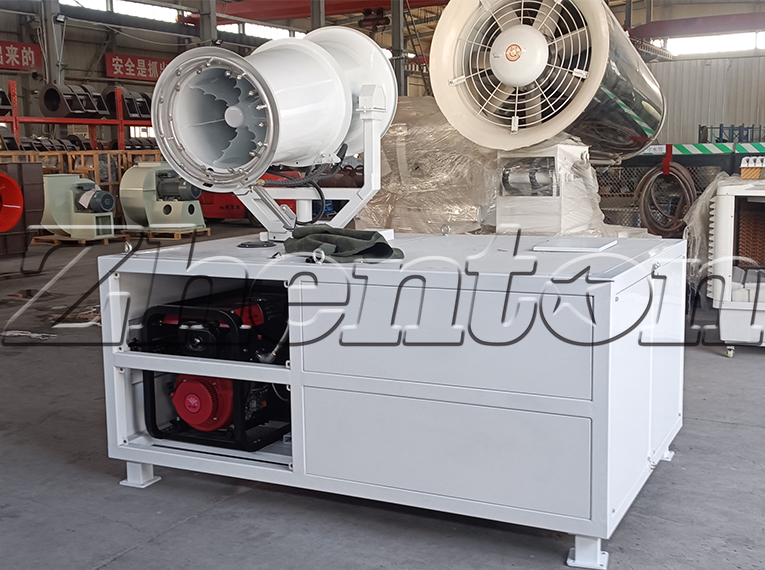

Discharge port dust is characterized by instant high concentration and complex particle distribution—when cement clinker is dumped from tankers into silos, the instantly raised dust has a large particle size span and diffuses in all directions with airflow. Aiming at this feature, the special mist cannon machine for discharge ports adopts a composite design of "short-range suppression + long-range coverage": the equipped high-pressure atomization system can generate ultra-fine mist droplets of 5-50μm, efficiently colliding with PM10, PM2.5, and other dust particles produced during discharging. Through the triple mechanism of "water mist adsorption - particle weight increase - gravity sedimentation," it rapidly suppresses diffusion within 10 seconds of dust rising. Field test data from a cement enterprise shows that after using this equipment, the dust concentration within 10 meters around the discharge port dropped from 85mg/m³ to 12mg/m³, with a dust suppression efficiency of over 85%.

Intelligent Linkage: Adaptive to Full-Process Control of Discharging Operations

Considering the intermittent nature of cement discharging operations, the mist cannon machine has a built-in dust concentration sensor that forms a linkage system with the discharge port solenoid valve. When the sensor detects that the dust concentration generated by material dumping exceeds the preset threshold (such as 50mg/m³), the equipment automatically starts and adjusts spray parameters simultaneously: during the aggregate discharging stage, it activates the 30° elevation angle spray mode, using the 6-level airflow generated by the fan to push the mist droplets to 5 meters above the silo, forming a "dust interception dome"; during the powder conveying stage, it switches to the 15° depression angle fine mist mode, making the mist droplets settle along the conveyor belt surface to avoid powder rising with belt operation. This dynamic response mechanism saves 30% more water resources than traditional timed spraying, while avoiding the lag of manual operation.

Explosion-Proof Design: Solving Application Challenges in High-Risk Environments

The cement discharge port area has a risk of dust explosion, so this mist cannon machine uses fully enclosed explosion-proof motors and anti-static spray pipelines, with key components certified by Ex d IIC T6 explosion-proof standards. In the application of a dry process cement plant, the equipment casing is made of 304 stainless steel, and the surface is treated with anti-static spraying, which can effectively prevent static electricity accumulation even in dry winter environments. At the same time, the spray system and electrical components are physically isolated, and with overload protection devices, it can automatically stop when dust accumulation causes the motor to overheat, eliminating ignition sources from the design level and providing dual safety guarantees for inflammable and explosive environments.

Energy Saving and Consumption Reduction: Reshaping the Economic Value of Environmental Protection Equipment

Compared with traditional water curtain dust removal devices, the mist cannon machine for discharge ports has particularly significant energy-saving advantages: its equipped variable frequency fan can automatically adjust the speed according to dust concentration, reducing the power to 1.5kW during low-dust periods, saving 40% more electricity than power frequency operation; the high-pressure pump adopts constant pressure water supply technology, automatically switching to energy-saving mode when the pipe network pressure exceeds 0.8MPa. Calculations by a cement plant with an annual output of 1 million tons show that this equipment reduces annual power consumption by 120,000 kWh compared with traditional dust removal equipment. Combined with the recycled spray wastewater, it saves 18,000 tons of water annually, reducing comprehensive operation and maintenance costs by 25%, and only needs 14 months to recover the equipment investment.

Scenario Adaptation: Unlocking Solutions for Diverse Discharging Conditions

Aiming at the differentiated needs of different types of discharge ports, this mist cannon machine provides modular configuration solutions: for the clinker silo top discharge port, it adopts a fixed + rotating bracket design to cover the circular silo 360°; for the cement powder bulk loading port, it is equipped with a telescopic spray arm that can automatically adjust the spray angle with the height of the tank truck; for the raw material yard discharge pit, it integrates a wind and dust suppression net with a mist cannon unit to form a composite prevention and control system of "physical barrier + mist droplet sedimentation." This customized solution has been applied in more than 20 projects of enterprises such as Conch Cement and China Resources Cement. Whether in open-air discharging or closed workshops, it can achieve a dust emission concentration ≤8mg/m³, meeting the requirements of the latest Emission Standard of Air Pollutants for Cement Industry.

In the green transformation process of the cement industry, the mist cannon machine for dust control at discharge ports is not only an environmental protection compliance technical equipment but also an intelligent assistant to improve production efficiency. With the concept of precise source control, it shifts dust control from end treatment to process management, constructing a sustainable development model of "clean production - healthy operation - low-carbon operation" for cement enterprises, and injecting new momentum into the high-quality development of the industry while protecting the blue sky.